Prediction of the paper properties

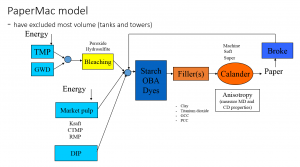

PaperMac is a library containing blocks for simulation of paper properties.

The PaperMac blocks can be combined with the regular FlowMac blocks to create models for a specific Paper Machine.

A PaperMac model is often a simplified process model, but still containing all the most important process units determining the paper properties.

The PaperMac customer will get meters for calculation of pulp and paper properties:

As a PaperMac customer You will be guided through the process of doing:

– Lab studies

– Data analysis and mathematical modelling

– Implementation of the results in PaperMac blocks (programming)

– Collection of mill data

– Calibrate the model against present paper grades

– Make a recipe for a new paper grade

Here is an example of a PaperMac study and the results of model calibration:

| PM X 42.5 | PM X 42.5 | PM X 45 | PM X 45 | PM X 48.8 | PM X 48.8 | |

| Mill | Simulation | Mill | Simulation | Mill | Simulation | |

| Kraft, % | 2.9 | 0 | 0.7 | 0 | 0.4 | 0 |

| TMP1+TMP2, % | 100 | 50/50 | 100 | 50/50 | 100 | 50/50 |

| Filler, % | 0 | 0 | 0 | 0 | 0 | 0 |

| DIP, % | 0 | 0 | 0 | 0 | 0 | 0 |

| Broke, % | 19 | 18.8 | 17 | 17 | 15 | 15 |

| BW, g/m2 | 42.2 | 42.5 | 44.7 | 45.0 | 48.4 | 48.8 |

| Moisture, % | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 | 9.4 |

| Density, kg/m3 | 657 | 657 | 657 | 659 | 661 | 661 |

| Thickness, my | 64.4 | 65 | 68.1 | 68 | 73.3 | 74 |

| Tensile, N/m | 2370 | 2432 | 2500 | 2574 | 2790 | 2801 |

| Tensile MD/CD | 3.03 | 3 | 2.98 | 3 | 2.95 | 3 |

| Tear CD, mN | 258 | 240 | 268 | 258 | 288 | 286 |

| ISO Bright, % | 58.1 | 59 | 58 | 58.7 | 58.1 | 58.6 |

| Opacity, % | 91.8 | 92.17 | 92.9 | 93.1 | 94.1 | 94.35 |

| DeltaE | 0.26 | 0.34 | 0.31 | 0.31 | 0.39 | 0.19 |

| CIE L* | 83.32 | 83.72 | 83.2 | 83.68 | 83.17 | 83.6 |

| CIE a* | -0.33 | -0.33 | -0.31 | -0.33 | -0.28 | -0.31 |

| CIE b* | 5.07 | 5.07 | 4.97 | 5.08 | 4.81 | 5.00 |

For more information and examples of use of PaperMac, contact Øivind Opdal.

By email to: oivind (a) opdal.net

By phone: +47 481 46 096